Outfitting Process in Ship Construction

Outfitting a ship is a complex process that involves the installation and integration of various systems and equipment on a vessel before it is put into service. This process is typically done in a shipyard and requires a significant amount of skilled labor and specialized equipment. According to a survey by the Shipbuilders Council of America, outfitting accounts for approximately 20–25% of the total cost of building a ship. Furthermore, research by the International Shipbuilding Progress (ISP) suggests that outfitting is one of the most time-consuming and labor-intensive stages of shipbuilding, with an average duration of 18–24 months for a large vessel.

One of the key challenges in ship outfitting is the coordination and integration of various systems and equipment. A study by the Society of Naval Architects and Marine Engineers (SNAME) found that poor coordination and integration can lead to delays and cost overruns, with an average cost impact of 5–10% of the total project cost. To mitigate these challenges, many shipyards are turning to advanced technologies such as Building Information Modeling (BIM) and virtual reality (VR) to improve coordination and integration during the outfitting process. A study by the National Research Council of Canada (NRC) found that the use of BIM can reduce coordination errors by up to 50%, while VR can improve the efficiency of the outfitting process by up to 30%.

Another important aspect of ship outfitting is the use of sustainable and eco-friendly technologies. According to a new study by the World Wildlife Fund (WWF), ships are responsible for nearly 3% of global greenhouse gas emissions. To combat this, shipyards are increasingly incorporating sustainable technologies such as solar panels, wind turbines, and hybrid propulsion systems into the outfitting process. These technologies not only help to reduce the ship’s environmental impact, but can also lead to cost savings in the long run.

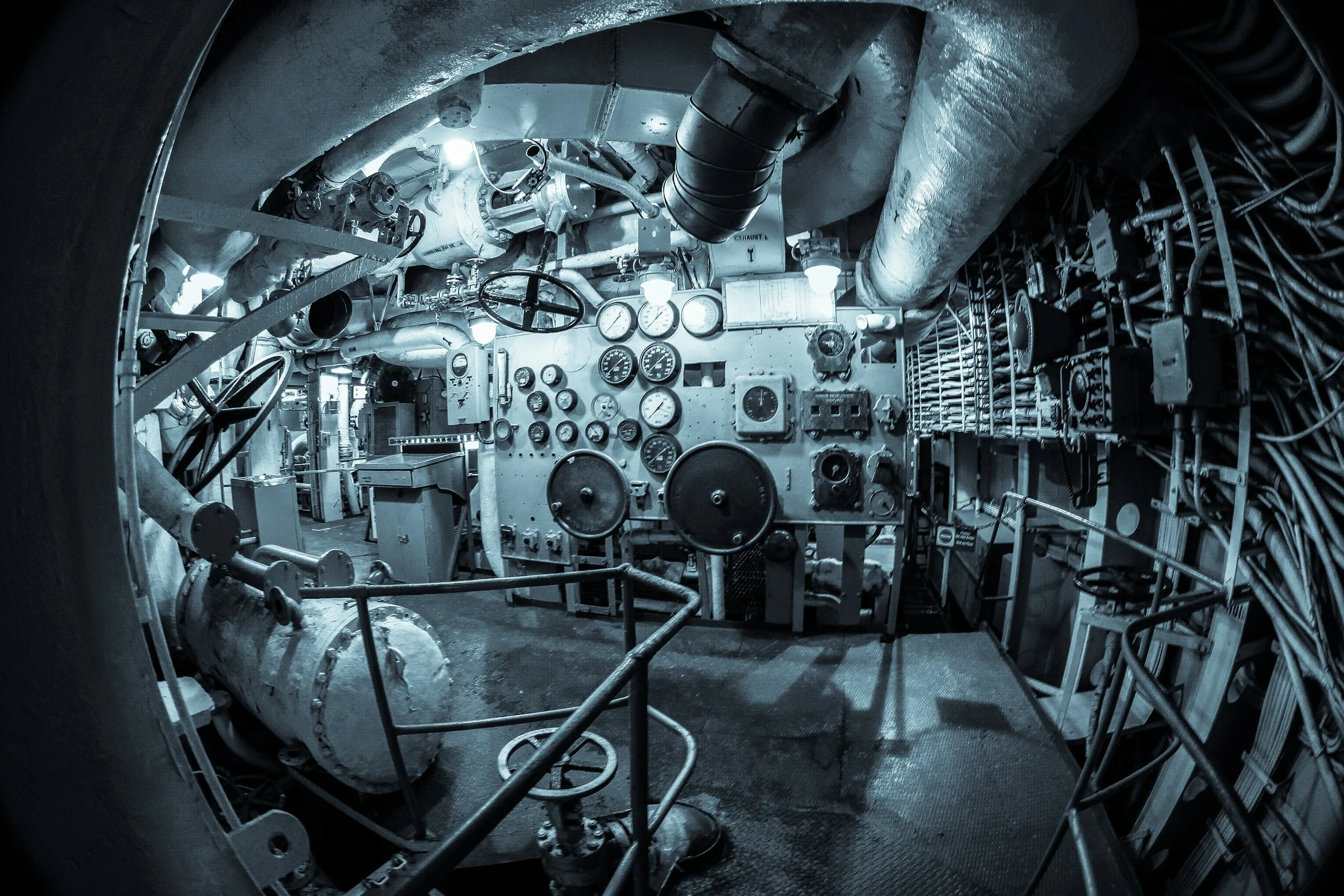

The outfitting process is divided into two main stages: the mechanical outfitting and the electrical outfitting. The mechanical outfitting stage involves the installation of all mechanical systems and equipment on the ship. This includes the propulsion system, which consists of the main engines, gearboxes, and propellers, as well as the ship’s auxiliary systems such as the bow thrusters, stabilizers and rudder systems. The propulsion system is a critical component of the ship and must be properly installed and configured to ensure the vessel can move efficiently and safely. In addition, the mechanical outfitting stage also includes the installation of navigation and communication equipment such as radar systems, GPS systems, and communication systems. These systems are essential for the safe operation of the ship and must be properly calibrated and tested before the vessel is put into service.

The electrical outfitting stage involves the installation of all electrical systems and equipment on the ship. This includes the installation of generators, switchboards, and other electrical components that are necessary for powering the ship’s systems and equipment. These systems must be properly installed and configured to ensure that they are safe and reliable. In addition, the electrical outfitting stage also includes the installation of lighting systems, air conditioning systems, and other electrical systems that are necessary for the comfort and safety of the crew and passengers.

During the outfitting process, various other systems and equipment are also installed, such as the plumbing and sanitation systems, which include the installation of fresh water systems, sewage systems, and other necessary components that are needed for the ship to function properly. Other mechanical and structural components are also installed during the outfitting process. This can include things like cranes, winches and other deck equipment that are necessary for the ship to operate efficiently and safely. The outfitting process is a critical and complex process that requires skilled labor and specialized equipment. It is essential that all systems and components are installed and configured correctly to ensure the safe and efficient operation of the vessel. The outfitting process is also subject to various regulations and standards that must be met, such as safety regulations and environmental regulations. The outfitter must ensure that the ship is built and fitted in compliance with the standards and regulations in order to be able to sail and operate legally.

Another important aspect of ship outfitting is the adherence to regulations and standards. The International Maritime Organization (IMO) and the International Convention for the Safety of Life at Sea (SOLAS) have established various regulations and standards for ship design and construction, including those related to safety and environmental protection. Research by the International Association of Classification Societies (IACS) has shown that compliance with these regulations can add an average of 5–10% to the cost of outfitting a ship.

In conclusion, outfitting a ship is a complex process that involves the installation and integration of various systems and equipment on a vessel before it is put into service. It is a critical and time-consuming stage of shipbuilding that accounts for a significant portion of the total cost. Coordination and integration, as well as compliance with regulations and standards are important challenges that can be addressed through the use of advanced technologies such as BIM and VR. Studies indicate that these technologies can help to improve efficiency and reduce costs associated with ship outfitting.

Eray Ceylan

Naval Architect and Marine Engineer